AMIABLE IMPEX, AI Earthing are the Biggest Manufacturer and Exporter, Suppliers of Exothermic Weld Powder and its Accessories Like Graphite Mould, Mould Handle / Clamp, Hand Gloves, Flint Gun,Soft & Hard Brush, Slag Remover, Sealing Compound, Flame Torch. We are specialist in Exothermic Weld Powder and also provide on site Training in India.

Exothermic Welding Connection is a way to connect the ground core with grounding, copper wires to copper wires. Copper wire with ground rod, Steel, copper, etc., with the high-efficiency heat used to connect grounding in the ground. This is a convenient and efficient process. Good connection The welding points are good for shock absorption and The cost of connection is relatively low when Compared to other welding processes such as gas welding welding, welding, exothermic welding, the two types of heat to be bonded . The heat is too high to melt. Both types of metal are heated. By spotting the powder, welding with a spark to ignite. Quickly do it together and coordinate with. Quick welding powder, rapid heating The advantages of this type of welding due to heat <a I = 17> happens very quickly, it makes welding possible. Different melting points (different metals, for example. Welding steel and copper) well due to heat Immediate, no heating Continuously, the molten metal melts first. Welding procedure Before welding, the metal must be cleaned. Apply it if there is a coating or paint to scrape. Make out the steel.

1. Assemble the mold to the metal to be welded.

2. Put the saucer in the welding mold.

3. Pour the powder into the welding mold to fill the socket.

4. Pour the spot in the zipper bag onto the surface. Welding face

5. Close the mold cover using a spot gun with a spark point.

6. The welding powder will ignite and flow into the melting pond.

7. Wait for the cold and then open the welding mold.

Exothermic Weld electrical connections supply from us will never loosen, corrode or increase in resistance. We are one of the largest manufacturer and exporter of Exothermic Weld Powder in India. Due to our Superior and Best Quality we are able to sell our product to Railways Contractors, Rail Metro, Telecommunications, Earthing and Lightning Installers Industries, as well as to Electrical Suppliers etc.

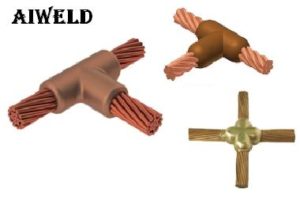

Type of Joints possible from Exothermic Weld:

1) Horizontal Joints

2) Vertical Joints

3) Straight Joints

4) Cross Joints

5) Overlap Joints

6) L shape Joints

7) T shape Joints

Features of Exothermic Weld:

– Superior electrical conductivity to the conductors themselves.

– Does not corrode, oxidize or degrade with time and is resistant to galvanic coupling.

– Able to withstand repeated electrical discharges.

– Never increases its resistance.

– Has greater mechanical and squeezing resistance than the conductors themselves.

– It has Superior electrical conductivity to the conductors themselves.

– It does not corrode, oxidize or degrade with time and is resistant to galvanic coupling.

– It is able to withstand repeated electrical discharges.

– It never increases its resistance.

– It has greater mechanical and squeezing resistance than the conductors themselves.

– It Offers a permanent weld and a low resistance connection, essential for achieving long wearing and trustworthy results in earthing.

– It Guarantees the most common connections not only between copper cables but also for welding tapes and metallic pieces made of brass, stainless steel, and copper coated steel earth rods.

Advantages of Exothermic Weld Powder :

There are many advantages of using Exothermic Weld. The most important one being that the process produces a molecular joint and not just a mechanical one in between the conductors. It is produced through a starting reactant which provides enough energy to activate the welding reaction. This takes place quickly and safely inside a graphite mould. The mould is designed specifically for a certain union depending on the elements to be welded and the joint type required. We guarantees all types of joints, not only copper cable unions but also to weld tapes, brass metallic pieces, stainless steel, steel ground rods covered with copper, etc. It is especially useful for joining dissimilar metals.

Why Use Exothermic Weld :

The Exothermic Weld Connection are solid molecular bonds, they do not loosen or corrode over the lifetime of connection. The ame cannot be said about other methods; such as brazing, crimp, split bolt, or compreion type connections.